Types of Oil Seals

Oil seals are rotary shaft seals that close a gap between stationary and moving components and prevent lubricant to escape and thus stop contamination through the clearance. There are different types of oil seals that fit a different application and surroundings and are made out of different materials. The right material and type of oil seal is determined by the application and the medium that will be used with the oil seal.

Norm design

The DIN 3760 standard specifies dimensions and requirements for materials, marking, use and installation of rotary shaft lip seals used for retaining fluid or grease in unpressurized equipment,

or equipment with a low differential pressure, that has rotating shafts. DIN 3761 defines standards for rotary shaft lip type seals for automobiles.

In the following table you will find the most important norm designs of oil seals according to the DIN standard and their corresponding ERIKS oil seal product.

| DIN | Standard 3760/3761 | ERIKS |

|---|---|---|

| A | rubber covered | R |

| AS | as type A with dust lip | RS |

| B | metal cased design | M |

| BS | as type B with dust lip | MS |

| C | double metal cased | GV |

| CS | as type C with dust lip | GVST |

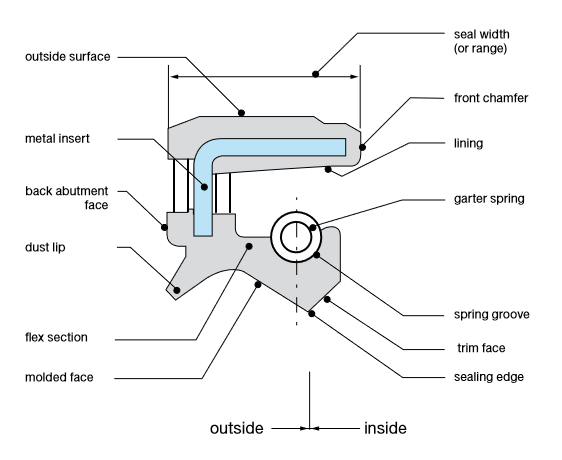

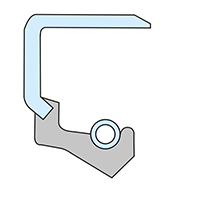

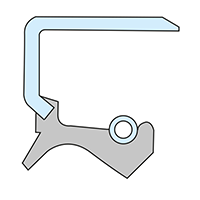

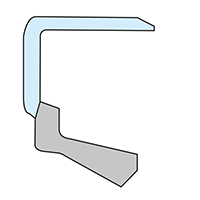

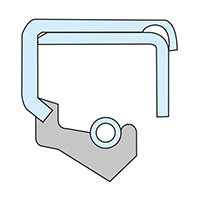

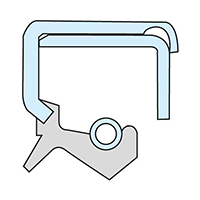

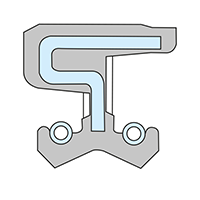

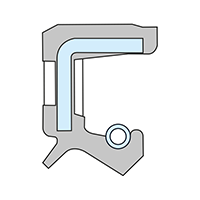

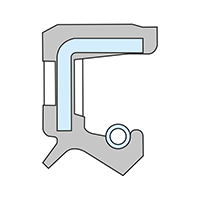

The standard oil seal consists of a metal ring as the inner skeleton which provides the structural stability to the oil seal. The outer part is made of rubber or metal - based on the requirement and the application of the oil seal. The spring on the lip of the oil seal provides support to the lip and prevents the lubricant from leaking outside and also prevents contaminants from entering.

The oil seal consists of a metal ring as the inner skeleton which provides the structural stability to the oil seal.

The outer part is made of rubber or metal - based on the requirement and the application of the oil seal.

The spring on the lip of the oil seal provides support to the lip and prevents the lubricant from leaking outside and also prevents contaminants from entering.

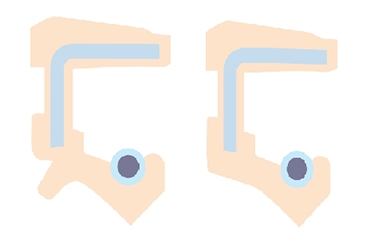

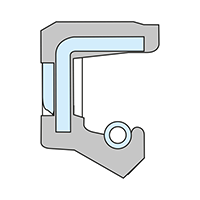

When present, the dust lip (which can be seen on the left oil seal in the picture) works to protect the sealing lip while blocking dust and dirt from entering the system, ensuring longer seal lifetime.

Dust lips are located on the inner diameter of the oil seal. An oilseal with dust lip may also be called a double lip oilseal.

Tip for greasing oil seals with dust lips:

If oil seals with fixed dust lips are being used, the space

between the sealing lip and the dust lip may also be filled

entirely with grease. The medium to be sealed will dissipate

the heat.

A garter spring is a coiled steel spring that is connected at each end to create a circular shape. It maintains the radial force exerted by the sealing lip around the shaft surface.

Types of oil seals

The most commonly used oil seals in most applications are rubber cased or metal cased oil seals. In the following chapter we will give an overview over the most important oil seals and their applications and specifications.

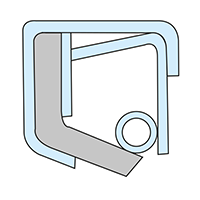

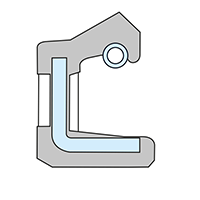

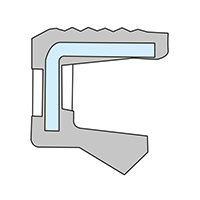

Metal Cased Oil Seals

Metal-cased oil seals are used when installed to a housing bore made of the same material. This allows for equal contraction and expansion of the materials during operation, preventing leakage from occurring. Typically metal-cased seals are more cost efficient than rubber seals.

| Picture | ERIKS type | Description | Find your oil seal |

|---|---|---|---|

|

M | Metal cased standard Oil Seal with vulcanised sealing lips. This type is frequently replaced by type R. According to the DIN Standard 3760, category B | View all M oil seals |

|

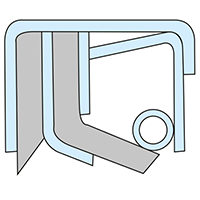

MST | Similar to type M but with additional dust lip. Applications are the same as type RST, when the requested type is not available. According to the DIN Standard 3760, category BS | View all MST oil seals |

|

MZV | Smaller sizes of Type M - only for applications such as needle bearings and grease seal. | |

|

GV | Totally enclosed metal casing for extra reinforcement, and a vulcanised rubber sealing lip. It is widely employed for larger shaft diameters for example in heavy industry such as roller bearings. According to the DIN Standard 3760, category C | |

|

GVST | Similar to type GV, but with additional dust lip. According to the DIN Standard 3760, category CS | |

|

GVP | Oil Seal with double metal case and assembled rubber sealing lip. Seals low pressures as well. It is available in almost every size from at least 100 mm inside diameter. | |

|

GVPST | Similar to type GVP, but with additional dust lip |

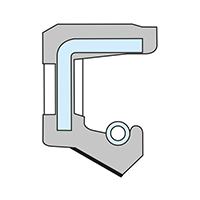

Rubber Cased Oil Seals

Rubber-cased oil seals are the most common oil seal execution, used when a metal-cased seal has the potential to fail (for example because of thermal expansion).

Oil seals with a rubber case cannot rust, in contrast to oil seals with metal cases. Moreover, oil seals with a rubber case can seal a lightly damaged housing much better than metal cased oils seals.

In high temperatures and high pressures, fast expanding rubber can provide a tight fit and more stable sealability.

The most commonly used type is type R. This type has a carbon steel insert and has rubber outside diameter. The rubber gives a good sealing capability,

even when the housing is not fully in tolerance. The sealing lip with spring provides interference on the shaft for effective sealing.

The outside diameter, with inner metal reinforcement case, allows press-fitting in the housing, with sufficient interference on the rubber to provide static sealing.

The sealing element is produced from a high performance Nitrile rubber. This in combination with a high quality galvanised steel garter spring gives the ERIKS Oil Seal an optimum life.

In order to prevent leakages due to a hydrodynamic pumping effect is it necessary that the sealing lip contact area on the sleeve or shaft is without any traces of machine lay.

Here is an overview of other commonly used oil seals with an outside rubber surface:

| Picture | ERIKS type | Description | Find your oil seal |

|---|---|---|---|

|

R | Rubber outer diameter with a carbon steel insert. Construction is in accordance with DIN 3760A (Category A) and available in both metric and inch sizes. | View all R oil seals |

|

R DUO | R type with two sealing lips, used for sealing two separate media. When the requested R-Duo type is not available, two R-types can be fitted back to back. | |

|

R EXT | This type has to be mounted on the shaft, and has the seal lip on the outside. It is used in wheel seal applications and is frequently used in centrifuges. | |

|

R-T | Oil Seal with a PTFE face bonded to the synthetic rubber element to reduce friction and heat development. Not available from stock. Its application is in Formula 1 engines. | |

|

RGZV | Smaller sizes only for applications such as needle bearings and grease seal but the outside surface has a ribbed design. | |

|

RST | Oil Seal with additional dust lip to prevent damage of sealing lip and to avoid the ingress of dust, dirt, water etc. into the system. Very commonly used in both metric and inch sizes | View all RST oil seals |

|

RST D | Seals pressures to 10 bar (1MPa) depending on the circumstances because it is more compact than type RST. It is recommended that our application engineers should be contacted. | |

| GR | Viton covered seal with completely encapsulated steel insert for high temperature and chemically aggressive applications; it is supplied with a stainless steel spring as standard. The Viton® used in the manufacture of Oil Seals is produced by DuPont Performance Elastomers. | View all GR oil seals | |

| GRST | Similar to Viton GR, but with an additional dust lip to prevent damage to the sealing lip and to prevent ingress of dust into the system. It is supplied with a stainless steel spring as standard. | View all GRST oil seals | |

| RZV | Smaller sizes only for applications such as needle bearings and grease seal. | View all RZV oil seals |