-Alt-2.png)

Custom Built Industrial Hose

The ERIKS Industrial Hose facility in Northampton supports both MRO and OEM customers with an extensive level of technical know-how, engineering capability and stock availability.

Our team of experienced application engineers and designers are on hand to convert your request into a finished and tested assembly in our purpose built and recently expanded production unit. Stocking a wide range of hose constructions and materials, we have the right type and bore of hose for your application, coupled to the DuraCrimp end termination system. Because Goodall manufacture both the hoses, ferrules and fittings, you are guaranteed a leak-free connection, as well as complete compatibility between hose and accessories to extend service life.

Ordering a hose assembly is simple, all we need to know are the type and size of end terminations, their orientation and the hose material and length, we can do the rest. Alternatively let us know the material the hose will hold, the working temperature and pressure and we can recommend a suitable hose, use our Priority Request for Quote form here.

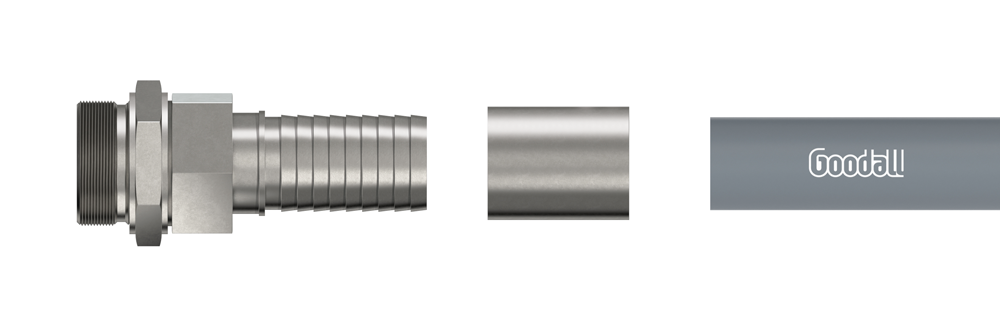

Goodall® DuraCrimp® Utility

Goodall® DuraCrimp® Utility is a new, exclusive, and safe crimping system for Goodall® Utility hoses.

The Goodall® DuraCrimp® Utility system is thoroughly tested to deliver the needs of the market and users:

An easy and safe coupling system for general-purpose applications:

- Air

- Nitrogen

- Water

- Aqueous solutions

- Oil etc.

Our new Goodall® DuraCrimp® Utility solution offers the following advantages:

- Increased safety and reliability

- Cost savings

- Couplings and ferrules made of Cr6-free carbon steel or stainless steel

- 3x different multipurpose hoses for a very wide range of industrial applications

- Superior compounds

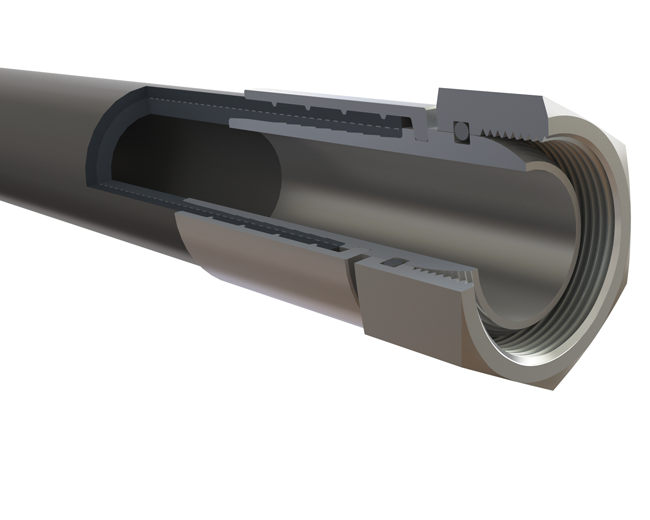

LEAK-FREE RELIABILITY FROM GOODALL

Because Goodall manufacture not just the hoses but the ferrules and fittings too, leak-free fitting

and complete compatibility between hose and accessories are all part of the package.

Titon Black

Tested according to ISO 1402

Construction:

- Full conductive hose construction

- Easy to handle, kink resistant, crush proof and flexible, even at cold temperatures

Applications:

- High quality multi-purpose hose handling compressed air, water and aqueous solutions

- The finest multi-purpose hose for the chemical, petrochemical and other industrial markets, but also for construction and agriculture applications where oil is not a factor

Standard lengths:

- Continuous long lengths on reels

- Fixed coil lengths

Temperature range:

- -40°C to + 95°C

Burst Pressure

- 4:1

Material Tube:

- Black, smooth and seamless EPDM rubber

- Extruded

- Electrically conductive R < 106 Ω

Reinforcements:

- 4 spiral polyester yarn

- High tensile strength

Material Cover:

- Black, smooth EPDM rubber compound

- Electrically conductive R < 106 Ω

- Extruded

- Heat, abrasion and extreme weather and ozone resistant

MultiServ

Tested according to ISO 1402

Construction:

- The grey cover is oil and greases resistant and doesn’t mark industrial floors

- Conductive tube

- Extremely flexible even at cold temperatures, easy to handle, kink resistant and crush proof

Applications:

- Premium high quality multi-purpose hose handling compressed air, water and aqueous solutions, oil, diesel and other petroleum based products

- Also suitable for chemical, petrochemical and other industrial markets, mining steel mills, shipyards, construction and agricultural applications

Temperature range:

- -30°C to + 95°C

Burst Pressure

- 4:1

Material Tube:

- Black, smooth and seamless NBRrubber

- Extruded

- Electrically conductive R < 106 Ω

- RMA Class A

Reinforcements:

- 4 spiral polyester yarn

- High tensile strength

Material Cover:

- Grey, smooth NBR rubber compound

- rma cLASS a

- Extruded

- Heat abrasion, weather and ozone resistant

Standard lengths:

- Continuous long lengths on reels

- Fixed coil lengths

MultiServ Black

Tested according to ISO 1402

Construction:

- Conductive tube

- Extremely flexible even at cold temperatures, easy to handle, kink resistant and crush proof

Applications:

- Premium high quality multipurpose hose handling compressed air, water and aqueous solutions, oil, diesel and other petroleum based products

- Also suitable for several industries: chemical, petrochemical and other industrial markets, mining, steel mills, shipyards, construction and agriculture applications

Temperature range:

- For air and oil applications: -40°C to +80°C

- For water applications: -30°C to 95°C

Burst Pressure:

- 4:1

Material Tube:

- Black, smooth and seamless NBR rubber

- Extruded

- Electrically conductive R ≤106 Ω

- RMA Class A

Reinforcements:

- Multiple spiral polyester yarn

- High tensile strength

Material Cover:

- Black, smooth NBR rubber compound

- RMA Class B

- Extruded

- Electrically conductive R ≤106 Ω

- High abrasion, weather and ozone resistance

Standard lengths:

- Continuous long lengths on reels

- Fixed coil lengths