Prevent damage to your

O-ring from improper use

O-rings are available in many shapes and sizes. The O-ring that you choose should match your specific application. This prevents any unnecessary damage to your seal and avoids leaks. There are various reasons why leaks can occur in your application. Read on to find out how to avoid them.

Causes of leaks

O-ring leaks can usually be traced back to three common causes. The main cause is the incorrect dimensioning of the O-ring combined with the groove dimensions. You can use our O-ring calculator to help you do this.

The second cause of leaks from seals is the excessive stretching or compression of the O-ring. This can cause the internal and external diameters of the O-ring to change. As a result, the O-ring may no longer fit correctly. To prevent this, ensure that the internal diameter is not expanded by more than 5% and the external diameter is not reduced by more than 3%.

The third cause of leaks is the incorrect choice of material or compound for your application. This can damage the O-ring and cause the seal to fail. Signs of damage that occur when the material does not match the application are listed below. We can also advise you on the right choice of material.

Tip! If you still have questions after reading this advice, please contact our O-ring specialists.

Most common signs of damage

Advice

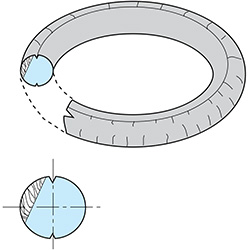

Extrusion

Extrusion is a phenomenon that occurs mainly in high-pressure applications. This is where the O-ring is trapped between the clearance gap and becomes "nibbled". The reason for this may be too wide a clearance gap or too high an operating pressure.

Advice

If your O-ring displays this sign of damage, there are various solutions

to avoid this in the future:

- If the pressure in your application is high and the correct clearance gap is present, use a harder material.

- Check that the maximum clearance gap is not exceeded. To do this, you can use our O-ring calculator.

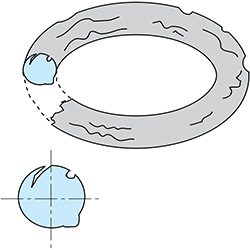

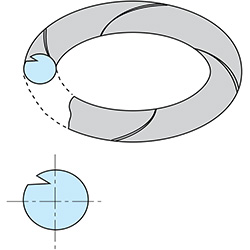

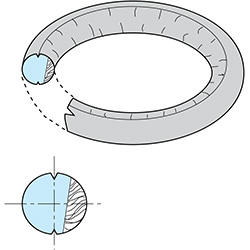

Twisting

In a dynamic application, an O-ring may start to rotate. This can cause the O-ring to twist and become damaged. This damage can be caused by a lack of lubrication, too high a compression or incorrect grooving.

Advice

Use a X-ring! These are specially designed for use in dynamic applications. X-rings require less compression and are

therefore subjected to less friction. The stability and sealing performance in dynamic applications is also higher than with an O-ring.

View our X-rings here.

If you still want to use an O-ring, choose the correct lubricant to ensure optimum lubrication of the O-ring. To do this, use silubrin grease or silicone oil.

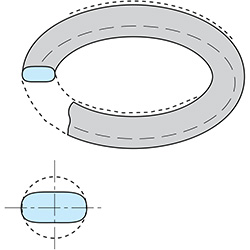

Compression set

The compression set is the degree of permanent deformation after the compression of an O-ring. If the load or deformation disappears, the material will soon return more or less to its original form. However, there is always a certain degree of permanent deformation. This is called the compression set. It is possible for the compression set of an O-ring to be high that it is no longer able to return to its original form. This can result in leakage.

Advice

There is considerable difference between the degree of compression set in O-ring materials. In any case, choose a material

with a better compression set or a higher temperature resistance. Some materials are even specially developed for use in an application that requires a low compression set (e.g.

for extended periods in hot water).

Perform a check on the groove dimensions in your application, as the compression set can be affected by the use of incorrect groove dimensions. Use our O-ring calculator.

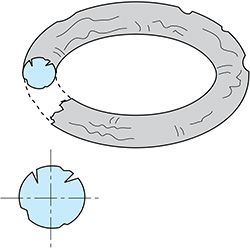

Effect of ozone

If the O-ring in your application has long-term exposure to direct sunlight, accelerated ageing may occur. Hairline cracks can arise, which are easily visible when the O-ring is stretched. The cracks are always perpendicular to the direction of tension.

Advice

Choose a compound with high age resistance and/or ozone resistance.

For example, consider HNBR,

EPDM and Viton. Take into account the other media the O-ring may come into contact with.

Overheating

If the O-ring in your application must be resistant to high temperatures, it is very important to also select a compound based on this. Every rubber compound has its own temperature range. If the working temperature is higher than the maximum temperature of the O-ring, hardening may occur and the O-ring will exhibit cracks in all directions.

Advice

Choose a compound that is suitable for the temperature of your application. Special materials are available for high

temperatures up to 327 degrees Celsius. For example, use silicone or FFKM.

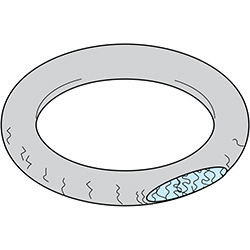

Explosion after decompression

Explosion after decompression can occur when gases are present in the rubber under high pressures. This is a phenomenon that industries such as oil and gas must take into account. As long as everything remains subjected to pressure, there is nothing to worry about. When the pressure drops, the gas trapped in the rubber expands. If the pressure is reduced gradually, the gas will leave the material in the normal way. If the pressure is reduced very quickly, the gas cannot leave in the normal manner and the rapid expansion of the gas may cause the material to explode.

Advice

ERIKS offers special EAD compounds to combat this phenomenon. Some of these compounds are tested in accordance with

NORSOK M710. The NORSOK M710 standard was developed by the Norwegian petroleum industry and sets out the requirements that must be met by rubber compounds for use in

applications in the oil and gas industry. View our FKM 514531, FFKM 0090 and HNBR 886516 compounds.

Installation damage

If you do not use the correct tools to install an O-ring, your O-ring may become damaged when it is fitted. For example, the O-ring could catch on a sharp part, causing part of it to break off. This may result in a leakage path and cause leaks.

Advice

Avoid sharp parts that may damage the O-ring. Use an

O-ring kit when installing or removing O-rings. This enables you to install your O-rings more

easily and remove them without causing damage. Also be aware of stretching your O-ring excessively or twisting it when fitting.