The five most common problems

with steam hoses

Steam plays critical role in many business processes. However, it is also dangerous and costly to work with.

It is therefore important to pay sufficient attention to your steam hoses, their fittings and the way in which

they are installed. The service life of steam hoses is determined on the one hand by the type of hose and the

way in which fittings are assembled, and on the other hand by how the user handles the hoses.

You can extend the service life of your hoses by following a number of rules/recommendations, which will also ensure the safety of the user. To help you extend the service life of your steam hoses, we have identified the five most common problems. In this article, we explain how to avoid them.

Problem 1. Damage from superheated steam

Steam exists in different states, which are determined by pressure and temperature. We can distinguish between three different states:

- Wet saturated steam

- Dry saturated steam

- Superheated steam

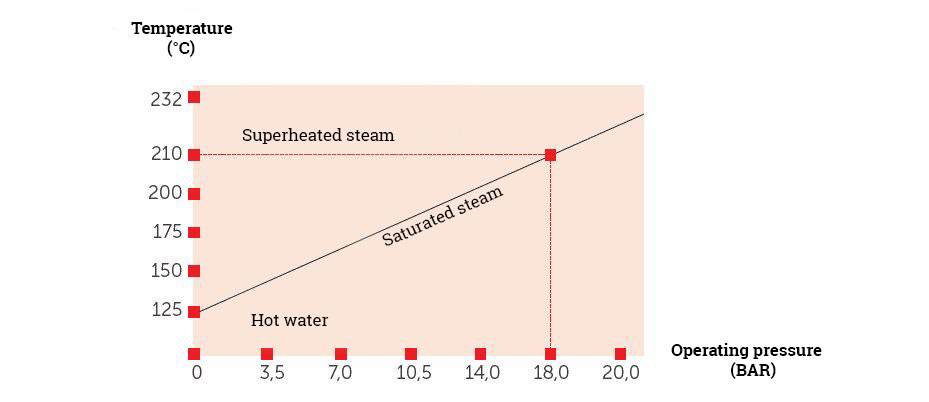

The diagram below shows how the combination of operating pressure and temperature creates either saturated or superheated steam. The points below the "saturated steam" line represent hot water, while the points above this line represent superheated steam.

NOTE! The use of saturated steam above the line will reduce the service life of steam hoses.

Saturated steam may or may not contain unvapourised water particles and can be "dry" or "wet" as a result. Saturated and slightly wet steam has a lubricating effect on the rubber inner wall of the hose, while overheated, and therefore dry, steam can harden the rubber inner wall by slowly continuing the vulcanisation process. This will reduce the service life of the rubber.

The best way to prevent damage from superheated steam is to use the chart above. Always keep a close eye on the combination of the operating pressure and temperature of your steam, and do not let the values rise above the line.

Problem 2. Popcorning of the inner wall

Popcorning refers to damage to the inside of the hose. This phenomenon is caused by the absorption of water

or water vapour by the pores in the inner wall. After use, the hose cools and condenses the steam into water,

which remains in the hose. When the cooled hose is next used, the trapped water vapour expands by a factor of

1600.

This sudden increase in volume creates air bubbles in the inner wall, causing the rubber to form blisters

that protrude from the inner wall. This blocks the hose and contaminates the steam with pieces of rubber. The inner surface of the hose looks like popcorn, hence the name.

One instruction when using steam hoses is to blow them dry and to make sure they are fully dry before storing them away. The process of blowing the hose dry is referred to as "Drain After Use". In reality, hoses are rarely blown dry, increasing the risk of popcorning. To avoid this problem, you can use a steam hose with an extruded inner wall in addition to draining after use. This extruded inner wall is seamless and homogeneous. In addition, the wall is made of a superior, gas-tight rubber that cannot be penetrated by water vapour and therefore avoids popcorning.

Problem 3. Rusting inlays

Steam hoses are fitted with steel inlays as standard. These are usually spiral wrapped and sometimes braided.

As the inner wall of most hoses is porous, the steam vapour looks for a way out. During this process, the water

vapour also comes into contact with the steel inlays, which starts the corrosion process. Because the rusting of

the inlays takes place below the surface and is not visible to the user, it can potentially lead to dangerous

situations.

The steel inlays are covered by the rubber of the outer wall. Once the oxidation process starts,

there is no way to stop it, especially if the hose is not used for extended periods of time. The danger is

that the inlays are weakened in such a way that the hose cracks and hot steam escapes, creating a lethal

situation for the user.

Even if a hose is being used with open steam, i.e. with free outflow, the hose can still burst. The unstoppable process of popcorning will clog the hose, resulting in less steam flowing from it. Experience has shown that users increase the steam pressure to continue to get enough steam from the hose. This increase in pressure can lead to the hose bursting open. The weakened inlays contribute to this risk.

Avoid rusting inlays, which can lead to dangerous situations, by using hoses with galvanised steel inlays. These inlays increase user safety and extend the service life of the hose considerably.

Problem 4. Identification

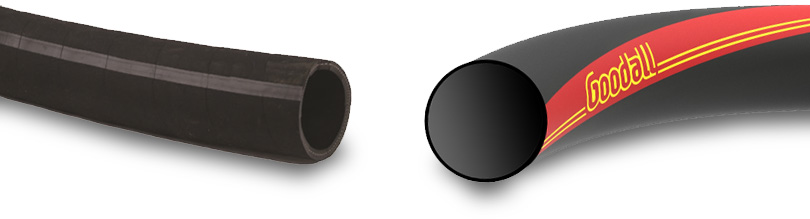

Steam hoses that are lying on the ground, are in use or are installed in tricky locations are often difficult to identify. Users find it difficult to tell which hose is which as the outer wall is often black in colour. This can cause dangerous situations due to the high temperatures and risk of combustion. To avoid these situations, steam hoses should be marked clearly according to the EN 6134-2A standard. The markings should state important product information such as the name of the producer, the standard with which the hose complies, the maximum operating pressure and the maximum permissible temperature.

Steam hoses must also have a red stripe down their entire length. This stripe is almost always a straight line running lengthways down the hose. This helps identify that the hose is a steam hose, but the way in which the hose is rolled up or is stored will determine whether the coloured stripe is visible or not. It is therefore important to use a spiral colour stripe with clear text printed on it. This means that it is always clear what type of hose it is, even if it is installed in areas that are hard to reach. The user then knows immediately that the hose is a steam hose and can take appropriate measures.

Problem 5. Steam leaks due to loose clamps

A leak in a hose could be due to a leak in the hose itself, or also to a loose clamp connection. In addition to causing steam loss, loose clamps can pose a danger to the user if the fitting shoots out of the clamp. Use the following solutions to avoid unnecessary costs and dangerous situations.

As a rule, steam hoses are fitted with (a) steel Boss clamping plates or (b) high-pressure brass gripper clamps. It is known that Boss fittings begin to leak after a period of time. This is caused by the oval shape of the clamping plates and the opening where the two-part plates connect to each other. The problem can be solved quickly and cost-effectively by shortening the hose and replacing the clamping plates on the hose nozzle. However, this is only a temporary solution as the problem will keep recurring — as a result, your hose will become shorter and shorter and your costs will rise.

A better solution is to use brass gripper clamps. These reduce the frequency of leaks, but do not eliminate them due to the space between the two-part grips. Retightening the bolts may be a simple solution. However, under intensive use, nuts and bolts can come loose in both Boss clamping plates and brass gripper clamps. If this happens during use, it can be dangerous for the user.

To put an end to steam leaks and loose fittings, use press sleeves. Press sleeves offer the following benefits:

- No loose bolts, meaning a safer working environment

- Lighter in weight and therefore easy to use

- No space between gripper clamps, the area prone to leaks

- Optimum grip on the inlays, creating a lasting connection

- No steam leaks, avoiding unnecessary costs

If you have any questions about steam hoses, get in contact with one of our specialists. They can provide you with more information and advise you on the best solution.